Leadership Matters

3/31/2017

Some years back I was involved in an auto repair business. We were developing a national chain of repair centers and while in the thick of it we had an objective of opening one store per month nationwide. While we built most of the stores from scratch, in some cases we bought existing shops and then converted them to our management system. There was one example in particular that I found to be demonstrative to the power of leadership. While we had several shops that got off to rocky starts, this store was particularly problematic. Over a year after opening we had several customer service, quality, and profitability issues. In most cases like this, we were able to temporarily move an experienced manager with a track record of success to a problem shop, where he would “fix the problem”. Generally, the “fix” was to fire the problem manager, hire a new one, and stand them up in our operating system. Sometimes more than once. It felt as though we were continually throwing spaghetti on the wall until we found one that would stick. However, this situation was different. There was a confluence of events that really didn’t allow us to simply shore up, fire, and replace the manager, so we had to try and work with the particular individual to solve the problem. All of this also coincided with our goal of more deeply developing our Lean management system throughout all our shops.

In this case our countermeasure was to focus intensely on teaching the individual the steps and behaviors that comprised our Leader Standard Work and Behaviors curriculum. In this case, more intensely than we ever had before. Now we all know that life is not like the fairy tales we were read as children, and as much as we would like for it to be otherwise, not every story has a happy ending. But in this case, within a matter of months, this one shop went from being our worst performing business to being among the top five in our system! I had to take a trip and spend some time with him to understand what happened. I knew Lean was powerful and I believed perhaps more than anyone in our car business that it was the key to our success. But I wasn’t prepared for such a dramatic turnaround. We will call him “Tom” for the sake of anonymity:

Joe- Tom, the turnaround in this shop has been nothing short of spectacular. I came to tell you how much I appreciate the work you’re doing here and to find out what the secret was.

Tom- Thank you Joe, yea we’re all pretty happy to see it too. I for one really need this job and it was obvious that I was on the way out if we didn’t turn things around.

Joe- But you’ve been in this business for a long time. In fact, your dad was in this business and you grew up working with him. What changed? Why couldn’t you succeed doing it the way you always did before?

Tom- Well, what I learned from being in this business my whole life was how to work around any problem that came my way. This particular shop had so many problems each and every day that that I couldn’t keep up with putting out all the fires. I couldn’t even prioritize which problem to work on first. I had customers, insurance companies, the regional manager, and you calling me all the time, changing my priorities, and telling me about yet another problem that flared up into some big fire.

Joe- This is an important experience for us as a company. What changed for you and this shop? All those factors are still here. We have customers, insurance companies, and yes managers like myself all with our own interests, pulling you in different directions. What changed?

Tom- Well, at first when we came up to headquarters and talked about this Lean stuff it was all interesting, but it didn’t really mean anything to me. I figured what the hell could this guy coming out of the aerospace industry, stamping out chicklets, possibly tell me about fixing cars, where everything is different every day. But suddenly it all became very different when my job was on the line. I didn’t have to be told that I couldn’t keep running this store the way it was performing. No one had to tell me that my job was at risk, but still my manager did in fact point that out to me very clearly. So you all had my attention. You could say it was my moment of truth. But you didn’t send another manager here to take over for me. Instead you sent someone here that really understood Lean and what I had to do to run this shop as a Lean operation. As we got into it and actually practiced the routines, it came over me. I actually now have a specific way to run this place. I know what is expected of me and what I have to do to be successful. I always knew how to put out the fires but I never really spent much time working on keeping them from becoming large problems to begin with. I have a process by which I can manage this place and lead my people. It’s literally changed my life.

Joe- So what can we learn from this? How can we bottle this up and spread it to all of our stores?

Tom- Well first of all, this can’t be a corporate headquarters exercise. At least not for me. This has to be learned at the front lines where work takes place. I grew up in this business and there is nothing that anyone can say in a conference room, removed from where the action is, that would have changed the way I run a store. It had to happen in the store. Someone had to come here and work with me. Walk a mile in my shoes and see what I see.

Tom- What really locked it into place for me was when my regional manager came and did his own Gemba walk. It’s hard to say that you’re too busy to do it for your own shop if the next level up has made time to come and do their own.

So locked up in this story are the lessons of Lean Leader Standard Work and Behaviors, and, the requirements of running a growing business.

If we go back to the first principle of Lean - engaging everyone, every day, everywhere looking for problems and becoming energized by engaging in solving them- then that places specific demands on leaders of such organizations. Those demands are different than the demands placed on successful leaders of MBO organizations. Management by Objectives requires a strong command of the performance data, an ability to hire people that can thrive in environments where there is competition among peers, improvisation is admired, and an ability to make tough and dispassionate decisions in cases where performance is lagging. The ultimate expression of this was Jack Welch’s “top ten/bottom ten” system of performance management.

This is not a question of whether or not you like or dislike the system dynamic underlying MBO anymore than you might prefer a screwdriver over a wrench. They are two very different tools used for different circumstances and one is not a replacement for the other. There was a very practical concern in the business described at the outset of this story. We were opening up a store each month, meaning that we needed a competent new store manager each month. We found ourselves caught in a “whack-a-mole” game of finding our best people and moving them to our worst problems over and over again. Our worst problem yesterday was not our worst problem today and yet another move would be required to solve today’s problem.

The problem was that we were focused on finding the exceptional 10% rather than creating a work environment where a much larger percentage of people could excel as we grew. One is a system destined to plateau, the other is a sustainable growth system. You will never have enough top ten percenters to support a sustained high growth operation. The math simply does not work.

Can your business persevere long term with only 10% of your people doing an exceptional job? Or are you in an environment where many more people are needed to do exceptional work consistently? Do you aspire to be an organization where a few really exceptional people are capable of overcoming the chaos of poor systems or do you need many really good people who can do an excellent job of executing brilliant processes that are continually improving? These are two very different work environments and equally different approaches to management.

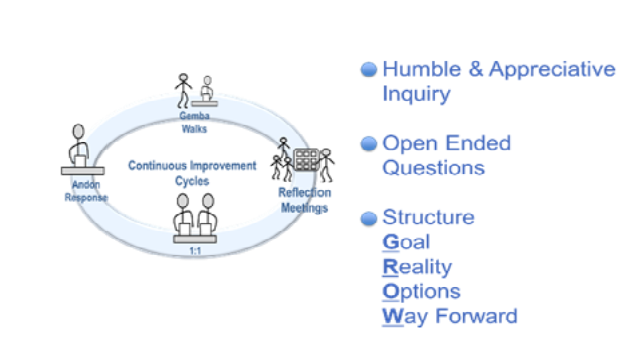

There are four major tools of Leader Standard Work. Reflection, Gemba, Andon, and 1 on 1. Reflection meetings are intended to be the venue where natural work groups come together and ask the questions of how did we do yesterday? What problems did we encounter? How can we do it better today? The leaders’ job is to frame up the issues on which their teams need to focus and build capability and enthusiasm around problem solving. These meetings would typically take place in front of visual process performance boards where the focus is on process capability. Gemba walks are exercises in “go see” where the primary objective is to understand what is really being done rather than relying on someone else’s rendition of the reality of the workplace. Andon’s are a communication to the entire team that a process is not yielding adequate results at the point in time when it occurs. One on ones are sessions where the leader coaches the longer term development of their subordinate in a focused manner.

The Activities and Behaviors of Lean Leadership

Throughout all four of these venues there are behavioral guideposts that are key to the success of the exercise. Without these behaviors you can in fact do significant harm and set back the progress the organization is trying to make in becoming a team based collaborative problem solving organization. There is an important difference between objective inquiry and interrogation.

Humble Inquiry is the cornerstone of Lean leadership behaviors. Edgar Schein did all of us a service by writing the seminal work on this subject under the same title. Appreciative Inquiry represents a broader dimension as it captures the essence of the difference between what we intend by “Gemba” and “Process Audit”. One implies a compliance detection and enforcement exercise. In these environments the measurement of success is based on the number of infractions discovered. Higher infraction rates warrant more Process Audits. Gemba on the other hand places the weight of coaching on the shoulders of leaders carrying out the exercise. In this case the measurement of success is the number of problems discovered and resolved i.e. implemented ideas per employee. More problems discovered and solved, the better the organization is working.

What we seek are leaders that are intensely curious about their organizations and the circumstances under which people within them do their work. Their sense of self worth comes from the growth they foster in their subordinates rather than checking off each problem as proof that that the organization needs them. They also understand that the worker is the person providing the value to the customer and that their role is to optimize that function as much as possible.

While these activities and behaviors take place at the front lines, they can’t be left to lower leadership alone. You can’t hire out your leadership responsibilities while you “run the company”. Leadership really does matter and leaders have to emulate the manner in which they want their subordinates to operate. We see examples of leaders all the time saying they want the front lines to adopt a Lean Management System, but not actually doing it themselves. The results are almost always the same. Mid and lower level leaders dedicated to carrying out the system to the best of their ability in the face of a prevailing opposing headwind. Making progress where they can and losing ground each time something stresses the system. No matter how dedicated. No matter how much one believes in a particular way of managing and leading the organization day to day, interactions will wear away our convictions and cause us to revert back to the predominant management model. This will almost always be defined by how the most successful in the organization behave. Either overtly or by inference, the message will be clear. If you want to succeed in this organization, this is the way we behave and act. Especially in the face of the inevitable stresses that we face in life. People watch your feet more than they listen to your mouth. Especially when things are not going perfectly. If you want them to react in a certain way, then you as the leader must demonstrate that. This responsibility can’t be subbed out, it’s up to each and every one of us throughout the ranks. The higher in the organization, the more important the role modeling. Can an organization be a Lean thinking team if its leaders are not? Probably not. There are always exceptions, but probably not.

We have covered the mechanics and the behaviors of leadership and now we can finally we get to the “tone” of leadership. I’ve been given a gift that will help perfectly explain the symbiotic relationship between leader and follower in a Lean thinking organization. The gift came wrapped in a New York Times article this past Sunday. This week the Vienna Philharmonic Orchestra turned 175 years of age. So what does this have to do with the Lean Management System? Well there is something very unique about this particular orchestra relative to most others. By their charter, they are self-governing. In their founding charter the composer Otto Nicolai wrote that the orchestra should allow its musicians to concentrate on what “gives us the certainty that we are something special”. They have no musical director that dictates their programs. However, they are not leaderless, they choose the conductors which will lead them. In 1992 their director Claudio Abbado was asked about what it was like leading such an organization. His observation was “I don’t direct them; I make beautiful music together with them”. I know this is a bit idealistic for the industrial environments where Lean was developed. But none the less it’s a vision to guide us as we grow the relationship between leader and followers. As leader you are part of the team with the responsibility to continually build their ability to discover and solve problems.

Whether you own the company or were promoted into your leadership position it makes no difference. We earn the right to lead. We shouldn’t abdicate this responsibility by tying ourselves up excessively with other activities that take us away from the act of leading. The conductor does not lead from the office.Leadership matters.

Joe Murli

What do you think?

Comments:

This post is more than 730 days old, further comments have been disabled.

Contact The Murli Group

Find out how we can help strengthen your company from the ground up»