Standard Work Development & Management

1 day

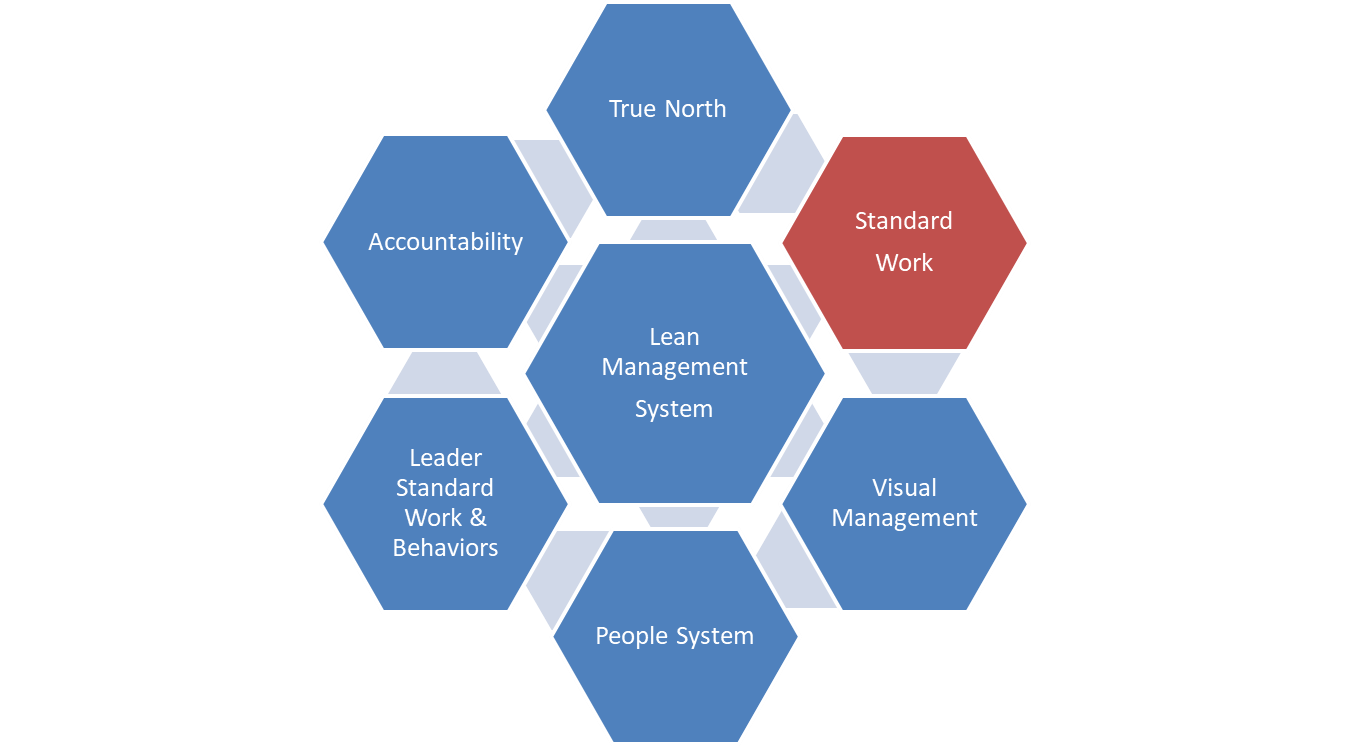

This course is a deep dive into the Standard Work element of the Lean Management System. It deals with developing an understanding of what it is, how it’s used, and how to best adopt its principles in your own organization regardless of industry.

Standard work is the current one best way that we know how to do something today – but that will improve ten times in the next ten months – and ten times again after that!

Very few organizations truly understand Standard Work as a requirement for organizational learning, and as such it’s a critical component of the Lean Management System (LMS). We define Standard Work as the current one best way that has been agreed upon regarding how to carry out a task and which continually evolves as ways are found to improve upon it. Not only is it a description of how to carry out a process, but it also consists of ‘Standards’ to provide a unified definition of what ‘good’ looks like. Just as importantly, there must be an agreed upon protocol and infrastructure to run controlled experiments when ideas for improvement are identified that will ultimately lead to improved Standard Work and a fully trained workforce, including leadership.

We can see from this that the concept goes well beyond the early simple definition of Takt Time, Work Sequence, and Standard Work in Process. It is the platform upon which the next improvement will be built and from which the organization continues to learn. When leaders carry out Gemba walks, they should be asking these basic questions.

- What is the work that is done here?

- Is there a standard?

- Is there a Standard Work?

- Is the Standard Work being adhered to?

- Are we getting the results that we need from this process?

- When was the last improvement made?

Without Standard Work, the Gemba walk is severely compromised. Essentially it becomes a social event with very few facts in front of the person doing the work or the leader.

The core elements of Standard Work include:

- Clear standards of “what good looks like”

- Instructions on how the work is done, including what tools and materials would be used. This is done to the level of detail required assuming the person carrying out the work has been fully trained to carry out the task.

- A clear protocol for identifying and solving problems in a team setting, including efficient approvals and technical support for experimentation.

- An efficient means of training the workforce on the newly accepted method

- Integration of the new method into Leader Standard Work

- Training that is carried out in a hands-on team setting utilizing multiple rounds of simulation as principles are introduced and built onto one another

The application of Standard Work is any circumstance in which team-based collaborative problem solving and learning are a desired state. This is true regardless of the industry, complexity, or variability of the process. It is simply table stakes if team members are to learn from one another and improve the way work is carried out for everyone. When it exists in concert with the other elements of the Lean Management System, capturing “the minds of the many” becomes a real possibility.

At the end of this workshop, you will be knowledgeable in:

- The elements that make work definition “Standard Work” rather than simply work standards

- The relationships among specifications, training and control documents, and standard work

- How the principles of Standard Work are applied in a broad range of applications from high volume mass production on one end of the spectrum to complex and variable knowledge work at the opposite end

- Its role in the process of Leader Standard Work and Behaviors

Prerequisites

It is assumed that attendees will have taken the Lean Management System course or have demonstrated LMS experience.

Who Should Attend?

- Leaders at all levels of the organization from executive to front line

- Lean support office personnel

Find out how we can help strengthen your company from the ground up»