Value Stream Mapping

Value Stream Mapping

1 Day On-Line Course

A Value Stream Map (VSM) displays the flow of process steps and information to deliver a product or a service to the customer. As a Lean management technique, Value Stream Mapping helps to visualize where there are barriers to flow in all major business processes. It provides a blue print for what specific actions need to be undertaken to speed up the flow of information, product, and cash. A comprehensive VSM exercise provides a concentrated forum to generate action plans which will eliminate waste and improve the customer experience overall.

When implemented properly, a VSM promotes a culture of continuous improvement that allows people to identify and remove waste from processes in order to improve efficiency. It also serves the purpose of developing cross functional cooperation among departments across the enterprise. This leverages improvements significantly over what can be achieved with a singular process or department and motivates higher quality team-based output.

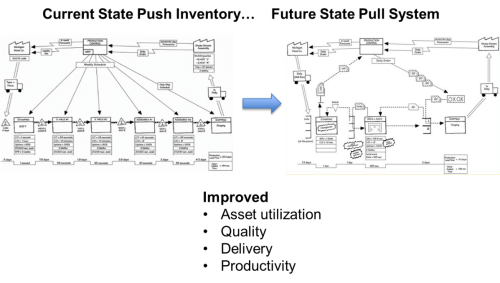

Elements of Value Stream Mapping include a current state VSM, a future state VSM, a Value Stream Improvement Plan (VSIP), Pulse Point Arrow, Leadership Standard Work, and visual War Room. The current state VSM provides a cross-functional team the opportunity to collaboratively develop a common view of where flow and quality issues exist as well as a common understanding of the overall impact beyond their own departmental boundaries. The future state map represents a desired as well as practically achievable future condition that represents a superior business model in terms of customer experience and business performance. The VSIP provides a detailed project plan that enables the management of the series of process improvements deemed necessary to achieve the future state. This visual management planning for the future state VSIP is carried out through a tool referred to as a Pulse Point Arrow (PPA). The PPA provides a plan for the back bone of visual tools that will enable effective Lean-based management techniques such as Gemba Walks and Team Reflection Meetings in the future state. This all culminates into a detailed roadmap for the overall Lean transformation. And finally, a Value Stream War Room is a visual management center which is established to track progress toward the future state vision and performance objectives. This center is necessary as value streams tend to be cross-functional and management is not typically accounted for in either physical workspaces or organizational design.

While the origin of Value Stream Mapping dates back to manufacturing and assembly lines, it is widely used today across a variety of industries and businesses. The tool is equally effective within product development, marketing, finance, Human Resources and administration, as it is in product or service processes.

Course Outline

- Define a Value Stream and a Value Stream Map

- Learn how to characterize the customer and understand the communication links between the customer, ourselves, and our suppliers

- Define the process steps in a Value Stream Map by which we create the product our customer buys

- Learn how to characterize the transportation/transmission of product in a Value Stream

- Identify the inventory throughout the Value Stream

- Identify the barriers to flow of value and learn how to determine and prioritize process improvement activities

- Understand the Value Stream Map in relation to the basic Lean concepts

- Learn how to create a future state vision

- Learn the purpose of and how to implement a War Room

- Learn how to develop a management plan to transition to the future state

- Understand why developing Leader Standard Work and Lean Leadership Behavior is required to achieve the future state

- Learn how to manage the transformation to fruition

Benefits

As a result of attending this workshop, you will be able to

- Develop an understanding of what Value Streams are and how to designate and manage them

- Create your own Current and Future State Value Stream Maps, Value Stream Improvement Plan, and visual War Room for moderately complex operations

- Prioritize and manage your process improvement activities over a one to three-year period

- Carry out the basic Leader Standard Work necessary for achieving the future state vision of your organization

Prerequisites

The Lean Management System overview course or equivalent

Who Should Attend?

- Business leaders

- Senior operations managers with cross functional responsibility

- Function Heads

- Process improvement support personnel

- Cross functional teams are especially powerful!

Find out how we can help strengthen your company from the ground up»